Company name: Bangkok Paper Business (BPB)

Spokesperson’s full name: Somphot Sanguanpiyapan

Designation: Managing Director

In the heart of Thailand's rich tapestry of industry and innovation lies the remarkable story of Bangkok Paper Business (BPB). For seven decades, BPB has been at the forefront of Thailand's paper industry, evolving from its pioneering roots to become a beacon of sustainability and progress. In this article, we delve into BPB's remarkable journey, tracing its origins to the early days of the Thai paper industry and uncovering the transformative path that led them to their current status as industry innovators. Join us as we explore BPB's commitment to sustainable practices, their collaboration with global partners, and their impact on Thailand's printing and packaging landscape.

Sanguanpiyapan: Since 1948, the first generation of Sanguanpiyapan’s family, Mr. Sanguan Sanguanpiyapan has started the first public paper for printing and packaging factory in Thailand together with four other alliances. The union of the paper factory was called “5 Tigers of Paper Industry” which had the most influence in Paper and Packaging industry at that time. This is the first powerful start of Sanguanpiyapan’s Family. In 1973, the second generation of Sanguanpiyapan’s Family established his own paper and packaging company with the name of “Bangkok Piyapan” in Thai was called “KrungThep Piyapan”. Because distributing a wide range of products for printing and packaging paper, “Bangkok Piyapan” was one of the top 50 companies in SET index.

From 1999, “Bangkok Piyapan” has been passed on the third generation’s hands and changed the company name to be “Bangkok Paper Business” or known as “BPB”. BPB has been accepted as a trustworthy paper and packaging company which got alliances with many well-known international printing and packaging manufacturers namely Siam Cement Group, Packaging Sector (SCGP); the biggest conglomerate company in Thailand, YUPO Corporation; the world-famous producer of synthetic paper from Japan, UPM Group; the world’s leading producer of environmentally friendly paper for printing and packaging, TAKEO; the high-profile paper company for premium colored and embossed paper, and Hansol; the legend paper mill from Korea who was keen on technology of recycled paper making for graphic printing and packaging applications.

BPB has built strong relationships with strategic partners who have common goals to keep making better sustainable printing and packaging materials in order to serve the future needs of industries.

Sanguanpiyapan: Since there are several ways to help improve our environment, especially when it comes to printing materials. BPB has strictly offered the concept of 3 Rs which is reduce, reuse and recycle. We have been working with many brand owners about printing and packaging design for their products’ end of life in the concept of “If the first button is pressed wrongly, the rest shall be wrong”. Our practice is aimed at reducing plastic with paper or specialty paper which can help end of life packaging so it is easier to be recycled and reused.

Today, many leading companies focus on carbon emission reduction. The reason behind is that the carbon emission reduction is something that can be measured, and it is very tangible. In addition, reducing plastic; means direct variation of reducing in carbon emission. The more you save using plastic, the more you minimize the carbon emission.

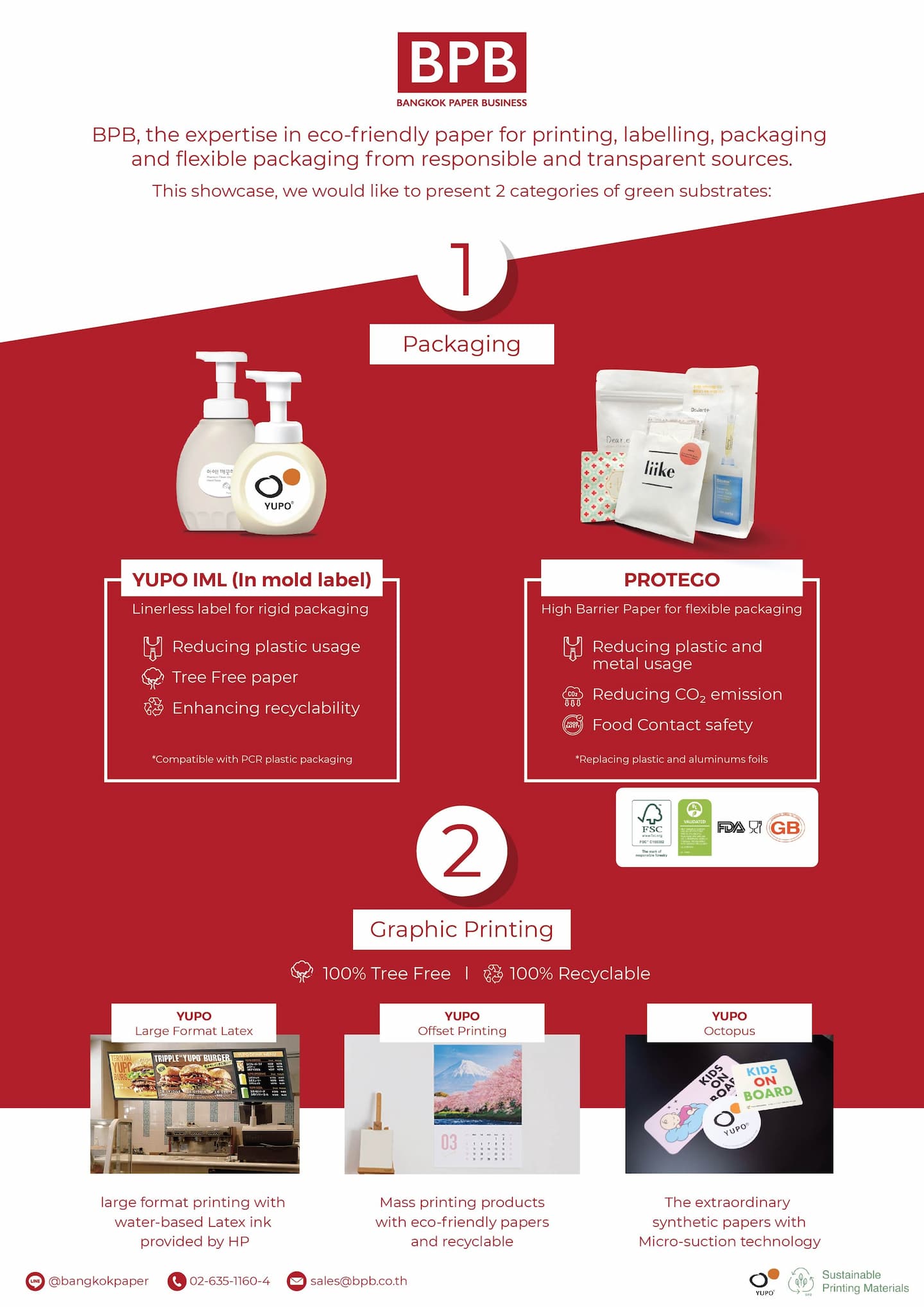

BPB has presented many types of paper or specialty paper that can be replaced plastic materials as much as today’s technology can make it possible such as high barrier paper for flexible packaging.

Moreover, if we look at “Reduce” such as reduction of waste in production line is another important thing. In-mold-labelling (IML) is the best example of reducing waste. It can help not only reduce sticker backing waste because it is linerless labelled, but also enhances the recyclability of plastic bottles.

Starting in 2021, BPB has been accepted as a trustworthy paper source for printing and packaging material as FSC™ Certified (License code FSC™ C168382). We have various recycled paper for many applications such as annual report, books, paper bags, colored paper box wrapping and special occasion cards.

We try to offer users the better greener choices of printing and packaging materials with reasonable price to make them more commercialize. We want to see the green materials to be used and not only used as a noble prize or something to be showcased.

Sanguanpiyapan: Because of being unique of any finished products, sizing of printing and packaging will be different. This is the reason why standard size of paper materials cannot be the answer for all. BPB offers a full range of services of paper converting, sheeting, slitting and rewinding in order to provide what customers need. Helping customers reduce cost and waste with customized paper and to deliver in a timely manner.

Sanguanpiyapan: BPB has complied with Sustainable Development Goals (SDGs) by United Nations: